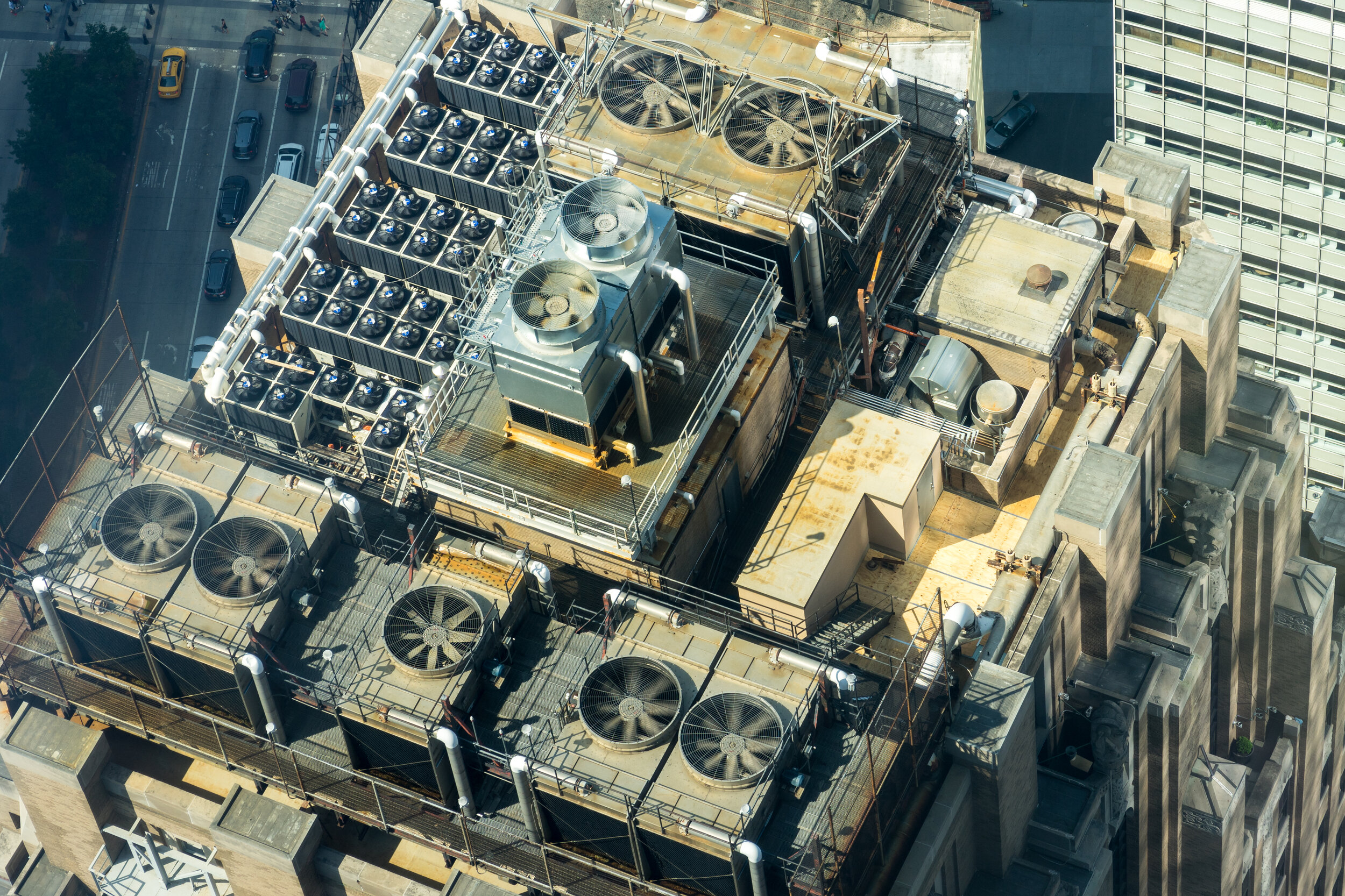

Cooling Water Treatment

It applies to systems that remove excess heat from any medium through a thermal exchange with water or air, in order to reduce the temperature of said medium to levels close to the environment, identifying two types: closed systems (closed circuits) and open systems (cooling towers).

Products

Closed Circuits

DuBois products are made with high quality raw materials (nitrite base), cutting edge equipment and formulations that ensure your system has superior protection against corrosion and deposits, obtaining a cleaner and more energy efficient system.

Assurance 3770

Blend of high-performance multi-metal corrosion inhibitors, dispersants and sequestrants specifically formulated for the effective control of corrosion and deposits in chilled and hot water closed systems containing Aluminum, Copper, Brass and Ferrous metals. It may also be used in certain open recirculating cooling water systems.

Assurance 3770 contains no Nitrite and is ideal for closed systems with open sumps, loosely-covered tanks, or high makeup rates, which are susceptible to oxidative losses as well as to bio-growth attack from both nitrifying and denitrifying bacteria.

Benefits:

Controls corrosion of both ferrous and “yellow” non-ferrous metals and alloy surfaces including Copper, Brass and Aluminum.

Prevents formation of galvanic cells or corrosion couples by conditioning any copper introduced with the makeup water.

Promotes the formation of a corrosion resistant gamma iron oxide complex.

Does not adversely affect valve-packing material, pump glands or water seals.

Nitrite-free formula eliminates the food source of both nitrifying and denitrifying bacteria, enabling more effective biocidal control.

Convenient, easy to feed liquid formulation permits optimum treatment control, eliminates batch mixing and promotes worker safety.

Omni-Gard

Balanced blend of inhibitors formulated to promote a more adherent protective film for corrosion inhibition. Omni-Gard is designed for corrosion protection of mild steel, copper and copper alloys in closed cooling systems.

Benefits:

Cost Savings: Concentrated product designed for large closed loop cooling water systems. Low end-use cost yields tremendous savings over conventional nitrite treatments used in large systems.

Superior Corrosion Protection: Measured corrosion rates on exposed coupons have been less than 1 mil per year.

Superior Deposit Control: Key benefit of Omni-Gard treatment is its ability to control deposits, particularly on heat transfer surfaces.

Low Conductivity: Omni-Gard treatment increases conductivity by less than 100 micromhos at a feedrate of 3 pints per 1,000 gallons; 375 mil per 1,000 L of system water. Greatly enhances operation of systems where low conductance is mandatory.

Easy to Test: Concentration of the Omni-Gard product in system water can be determined easily by using a WT 1925 (409228) Test Kit or WT 2001 (409231) Test Kit.

Thorogard

Balanced blend of inhibitors formulated to promote a more adherent protective film for corrosion inhibition. Thorogard is designed for corrosion protection of mild steel, copper and copper alloys in closed cooling systems. Deposit control agents in this product maintain clean heat transfer surfaces. Thorogard imparts a brilliant green color to the water, thus leaks may be detected.

Benefits:

Cost Savings: Low end-use cost yields tremendous savings over conventional nitrite treatments.

Superior Corrosion Protection: Measured corrosion rates on exposed coupons have been less than 1 mil per year.

Superior Deposit Control: Key benefit of Thorogard treatment is its ability to control deposits, particularly on heat transfer surfaces.

Low Conductivity: Increases conductivity by less than 100 micromhos at a feedrate of 10 pints per 1000 gallons of system water. Greatly enhances operation of systems where low conductance is mandatory.

Easy to Use: Concentration of the Thorogard product in system water can be determined easily by using a WT 1925 Test Kit or WT 2001 Test Kit.

Cooling Towers

Formulated without nitrite, which provides superior performance for open systems where high inhibitor losses are suffered by excessive exposure to oxygen (open pits) or where too much air enters with make-up water.

Omnitrex

Highly concentrated, non-chromated alkaline treatment primarily for large cooling tower systems. Omnitrex treatment provides superior scale control and corrosion control in systems using high hardness and alkalinity makeup waters. It is a synergistic blend of anti-scalants, dispersants and corrosion inhibitors for maintaining efficiency of cooling systems.

Benefits:

Cost Effective: Concentrated blend of scale and corrosion inhibitors make treatment of large systems economical.

Optimum Efficiency: The unique blend of scale and corrosion inhibitors allows higher hardness (up to 1000 ppm) and alkalinity (up to 500 ppm) than most competitive programs. This allows for high cycles of concentration with less chance of energy-robbing scale formation.

Penetrex

This dispersant/antifoulant product is a specially formulated low-foaming dispersant. It is highly effective in dispersing microbial growth, oil and sludge in cooling water systems. Penetrex antifoulant will help to remove deposits which reduce heat transfer and which lead to under-deposit corrosion. It enhances the performance of oxidizing and nonoxidizing biocides by penetrating and dispersing microbial growth.

Benefits:

Enhancement of cleanup operation: Addition of the Penetrex dispersant to a Deep Crystal cleanup of a fouled tower system will speed up the cleaning process by penetrating algae mats and slime masses in those hard-to-reach areas.

Adjunct to regular microbiological treatment: Enhances the performance of oxidizing and nonoxidizing biocides by penetrating and dispersing microbial growth.

Disperse bacterial slime: Slime can be one of the most problematic of microbiological growths in cooling towers. The addition of Penetrex dispersant/antifoulant to a fouled system will loosen slime so that it can be bled out of the system. Thereafter, Penetrex dispersant can be fed continuously to control deposition of new slime masses.

Cleans up oil in cooling towers: Oil often gets into cooling towers and no amount of flushing the system can alleviate this problem. The Penetrex product, with its specially formulated dispersant, will emulsify the oil and allow the system to be flushed clean. For systems with continuous oil leaks, Penetrex dispersant will keep the oil in suspension longer to allow it to be bled from the system.

Greater corrosion protection: The deposition of microbiological growth can cause and accelerate corrosion in a tower system. Penetrex treatment will help to remove deposits which reduce heat transfer and which can lead to under-deposit corrosion.

Supertrex PBB

Solid (powder) DRUM-FREE cooling water treatment blend of corrosion inhibitors and scale control agents which provide superior scale and corrosion control to critical cooling systems using high hardness, high alkalinity makeup water. This product has been successfully used in waters approaching +3.3 LSI. Supertrex PBB comes in a solid (powder) form to reduce shipping costs and simplify delivery of the product to hard-to-reach locations. The contents of the Supertrex PBB pouch are easily dissolved in a PBB SYSTEM to make a liquid product, Supertrex PBB Blend. This Supertrex PBB Blend can then be fed from the reservoir directly into the cooling tower.

Benefits:

The ultimate advancement in cooling water chemistry.

Highest hardness and alkalinity control available (even in critical cooling systems).

Eliminates drum handling and disposal costs.

Reduces freight and storage costs.

Safety in handling small package.

No complicated delivery system.

Innovative "Tracer" method eliminates hassles of traditional phosphonate testing.

Supertrex

Exclusive blend of corrosion inhibitors and scale control agents which provide superior scale and corrosion control to systems using high hardness, high alkalinity makeup waters. This multi-functional blend of antiscalants, dispersants and corrosion inhibitors is outstanding for maintaining the efficiency of open recirculating cooling systems.

Benefits:

Simple to Use: All the scale and corrosion-inhibiting chemicals needed to maintain maximum rates of heat exchange efficiency are combined in a single-liquid blend, fed into the system from the shipping container.

Advanced Water Chemistry: Lower, more economical dosage rates and higher solids retention levels in the tower water are attainable with Supertrex, due to the low molecular weight polymeric dispersants.

Hardness Control: Tolerates hardness up to 1000 ppm, higher hardness than most tower treatment products.

Higher Alkalinity Limits: Tolerates M Alkalinity up to 500 ppm, higher than most tower treatment products.

Higher Temperature Control: Withstands higher temperatures in cooling tower water than most cooling tower treatment products.

Ultrex PBB

Blend of corrosion inhibitors and scale control agents which provide superior scale and corrosion control to critical cooling systems using high hardness, high alkalinity makeup water. This product has been successfully used in waters approaching +3.3 LSI. Ultrex PBB comes in a solid (powder) form to reduce shipping costs and simplify delivery of the product to hard-to-reach locations. The contents of the Ultrex PBB pouch are easily dissolved in a PBB SYSTEM to make a liquid product, Ultrex PBB Blend. This Ultrex PBB Blend can then be fed from the reservoir directly into the cooling tower.

Benefits:

The ultimate advancement in cooling water chemistry.

Highest hardness and alkalinity control available (even in critical cooling systems).

Eliminates drum handling and disposal costs.

Reduces freight and storage costs.

Safety in handling small package.

No complicated delivery system.

Innovative "Tracer" method eliminates hassles of traditional phosphonate testing.

Corporate Headquarters

Address: Av. Industrias Pte 1200

Col. Bella Vista

Monterrey, Nuevo León, México, C.P. 64410

Phone: +52 81 8625 5600